Paper mill waste could unlock cheaper clean energy

- Date:

- December 11, 2025

- Source:

- Shenyang Agricultural University

- Summary:

- Scientists developed a high-performance hydrogen-production catalyst using lignin, a common waste product from paper and biorefinery processes. The nickel–iron oxide nanoparticles embedded in carbon fibers deliver fast kinetics, long-term durability, and low overpotential. Microscopy and modeling show that a tailored nanoscale interface drives the catalyst’s strong activity. The discovery points toward more sustainable and industrially scalable clean-energy materials.

- Share:

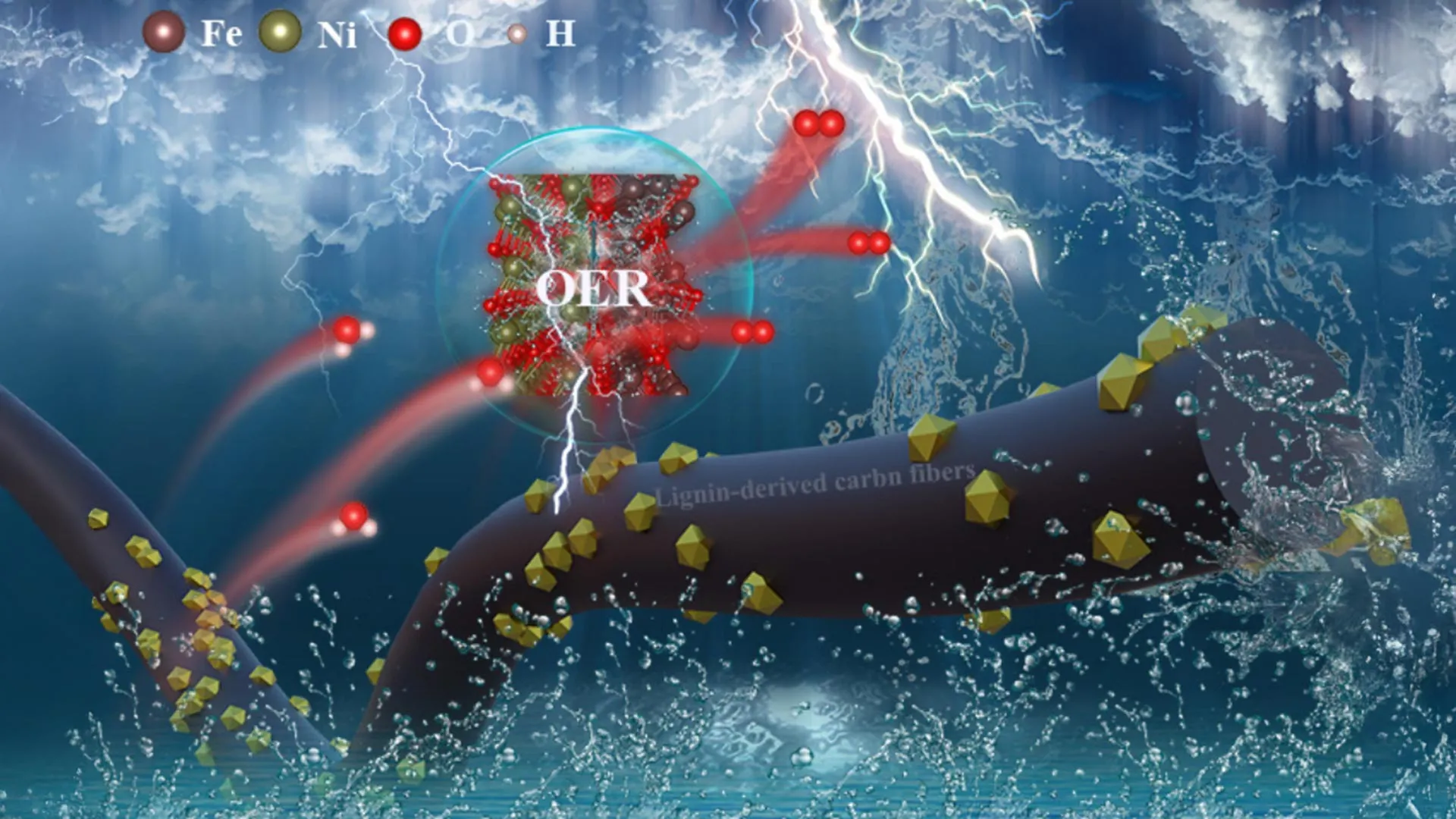

Researchers have developed a catalyst sourced from renewable plant waste that shows strong potential for speeding up clean hydrogen production. The material is produced by embedding nickel oxide and iron oxide nanoparticles into carbon fibers made from lignin, creating a structure that improves both efficiency and durability during the oxygen evolution reaction, a crucial part of water electrolysis.

The study, published in Biochar X, reports that the catalyst reaches a low overpotential of 250 mV at 10 mA cm² and remains highly stable for more than 50 hours when operating at elevated current density. These performance levels point to a viable, low cost alternative to the precious metal catalysts typically used in large-scale water splitting.

"Oxygen evolution is one of the biggest barriers to efficient hydrogen production," said corresponding author Yanlin Qin of the Guangdong University of Technology. "Our work shows that a catalyst made from lignin, a low-value byproduct of the paper and biorefinery industries, can deliver high activity and exceptional durability. This provides a greener and more economical route to large-scale hydrogen generation."

Transforming Lignin Into a Functional Carbon Framework

Lignin is one of the most abundant natural polymers, yet it is often burned for minimal energy return. In this work, the team converted lignin into carbon fibers using electrospinning and thermal treatment. These fibers serve as a conductive and supportive framework for the metal oxide particles. The resulting catalyst, known as NiO/Fe3O4@LCFs, contains nitrogen-doped carbon fibers that offer fast charge transport, high surface area, and strong structural stability.

Microscopy revealed that the nickel and iron oxides form a nanoscale heterojunction within the carbon fiber structure. This interface plays a central role in the oxygen evolution reaction by helping intermediate molecules bind and detach at optimal rates. Pairing these metal oxides with a conductive carbon network improves electron movement and prevents the particles from clumping together, which is a frequent issue in conventional base metal catalysts.

Verified Activity Through Advanced Testing

Electrochemical measurements showed that the material performs better than catalysts containing only one metal, especially under the high current conditions needed for real world electrolysis systems. The catalyst also exhibits a Tafel slope of 138 mV per decade, indicating more rapid reaction kinetics. Additional evidence from in situ Raman spectroscopy and density functional theory calculations supports the proposed mechanism, confirming that the engineered interface efficiently drives oxygen evolution.

Scalable Design Using Widely Available Biomass

"Our goal was to develop a catalyst that not only performs well but is scalable and rooted in sustainable materials," said co-corresponding author Xueqing Qiu. "Because lignin is produced in huge quantities worldwide, the approach offers a realistic path toward greener industrial hydrogen production technologies."

The findings underscore the increasing value of biomass-derived materials in energy conversion applications. Combining renewable carbon supports with carefully designed metal oxide interfaces aligns with global efforts to create low cost and environmentally friendly clean energy technologies.

The researchers note that this method could be adapted to different metal combinations and catalytic reactions, opening new opportunities for designing next generation electrocatalysts based on abundant natural resources.

Story Source:

Materials provided by Shenyang Agricultural University. Note: Content may be edited for style and length.

Journal Reference:

- Xuezhi Zeng, Yutao Pan, Yi Qi, Yanlin Qin, Xueqing Qiu. Lignin-derived carbon fibers loaded with NiO/Fe3O4 to promote oxygen evolution reaction. Biochar X, 27 November 2025 [abstract]

Cite This Page: