MIT just made aluminum 5x stronger with 3D printing

MIT just engineered a printable aluminum that’s stronger, lighter, and tough enough to reshape the future of flight.

- Date:

- December 29, 2025

- Source:

- Massachusetts Institute of Technology

- Summary:

- MIT researchers have designed a printable aluminum alloy that’s five times stronger than cast aluminum and holds up at extreme temperatures. Machine learning helped them zero in on the ideal recipe in a fraction of the time traditional methods would take. When 3D printed, the alloy forms a tightly packed internal structure that gives it exceptional strength. The material could eventually replace heavier, costlier metals in jet engines, cars, and data centers.

- Share:

MIT engineers have created a new aluminum alloy that can be 3D printed, tolerates extreme heat, and reaches strength levels far beyond conventional aluminum. Tests show the material is five times stronger than aluminum made using standard manufacturing techniques.

The alloy is produced by combining aluminum with several other elements, chosen through a process that blends computer simulations with machine learning. This approach dramatically narrowed the search for the right recipe. Traditional methods would have required evaluating more than 1 million possible material combinations, but the machine learning model reduced that number to just 40 promising options before identifying the optimal formula.

When the researchers printed the alloy and put it through mechanical testing, the results matched their predictions. The printed metal performed on par with the strongest aluminum alloys currently produced through traditional casting.

A Lighter Metal With Big Industrial Potential

The team believes the new printable aluminum could lead to stronger, lighter, and more heat-resistant components, including fan blades for jet engines. Today, those blades are typically made from titanium -- which is more than 50 percent heavier and can cost up to 10 times more than aluminum -- or from advanced composite materials.

"If we can use lighter, high-strength material, this would save a considerable amount of energy for the transportation industry," says Mohadeseh Taheri-Mousavi, who led the research as a postdoc at MIT and is now an assistant professor at Carnegie Mellon University.

John Hart, the Class of 1922 Professor and head of MIT's Department of Mechanical Engineering, says the benefits extend well beyond aviation. "Because 3D printing can produce complex geometries, save material, and enable unique designs, we see this printable alloy as something that could also be used in advanced vacuum pumps, high-end automobiles, and cooling devices for data centers."

Details of the work appear in the journal Advanced Materials. MIT co-authors include Michael Xu, Clay Houser, Shaolou Wei, James LeBeau, and Greg Olson, with additional collaborators Florian Hengsbach and Mirko Schaper of Paderborn University in Germany, and Zhaoxuan Ge and Benjamin Glaser of Carnegie Mellon University.

From Classroom Challenge to Materials Breakthrough

The project traces its roots to an MIT course Taheri-Mousavi took in 2020, taught by Greg Olson, professor of the practice in the Department of Materials Science and Engineering. The class focused on using computational simulations to design high-performance alloys. Alloys are made by combining multiple elements, and the specific mix determines strength and other key properties.

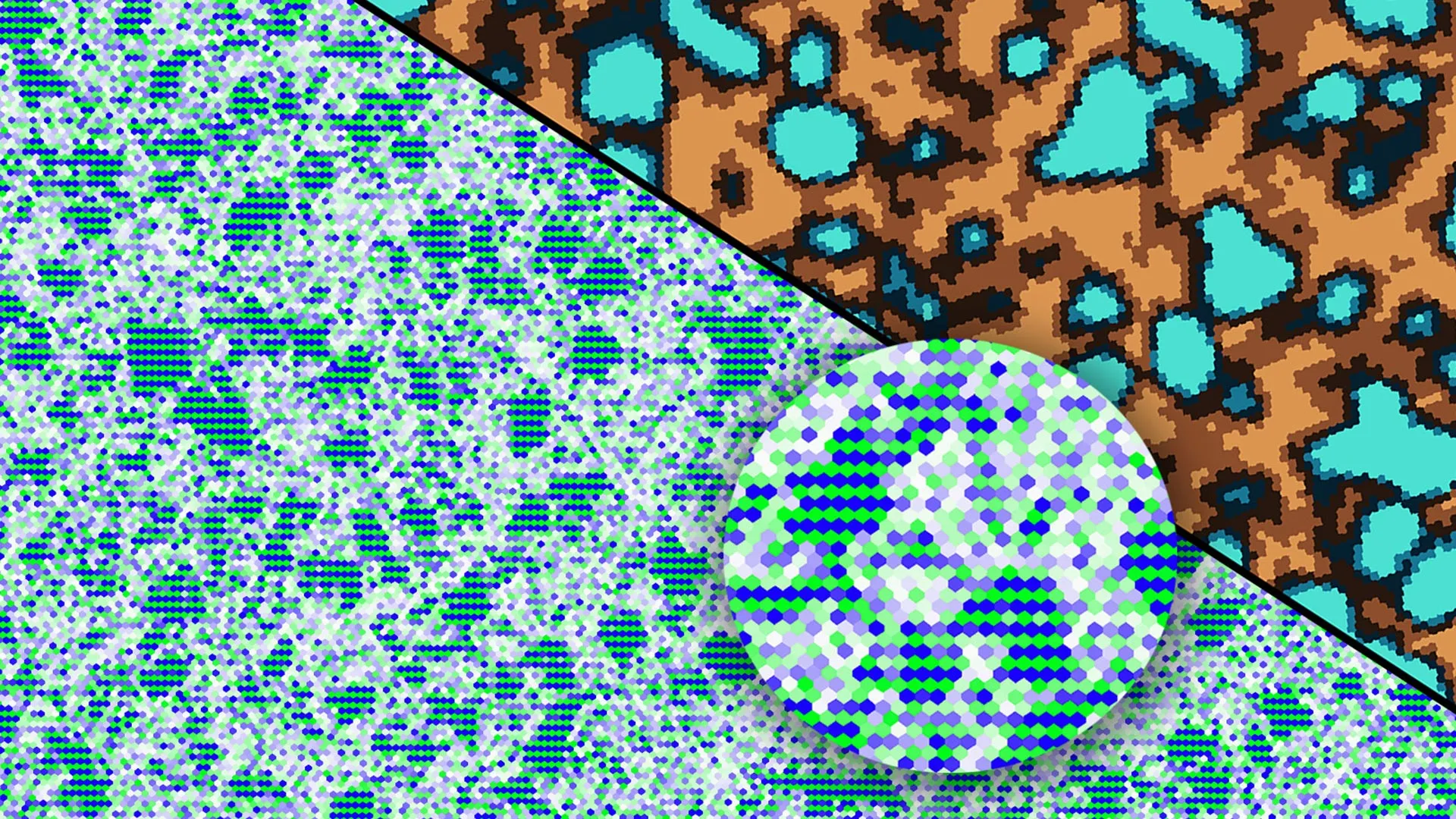

Olson challenged students to develop a printable aluminum alloy stronger than any that existed at the time. Aluminum's strength depends heavily on its microstructure, particularly the size and density of tiny internal features called "precipitates." Smaller, more closely packed precipitates generally result in a stronger metal.

Students used simulations to test different combinations of elements and concentrations, attempting to predict which mixtures would produce the strongest alloy. Despite extensive modeling, the effort did not outperform existing printable aluminum designs. That outcome prompted Taheri-Mousavi to consider a different approach.

"At some point, there are a lot of things that contribute nonlinearly to a material's properties, and you are lost," Taheri-Mousavi says. "With machine-learning tools, they can point you to where you need to focus, and tell you for example, these two elements are controlling this feature. It lets you explore the design space more efficiently."

Using Machine Learning to Redesign Aluminum

In the new study, Taheri-Mousavi picked up where the class project ended, applying machine learning methods to search for a stronger aluminum alloy. These tools sifted through data on elemental properties to uncover patterns and relationships that traditional simulations often miss.

By analyzing only 40 candidate compositions, the machine learning system identified an alloy design with a much higher proportion of small precipitates than previous attempts. This structure translated directly into greater strength, surpassing results obtained from more than 1 million simulations conducted without machine learning.

To actually create the alloy, the researchers turned to 3D printing rather than conventional casting, which involves pouring molten aluminum into a mold and allowing it to cool slowly. Longer cooling times allow precipitates to grow larger, which reduces strength.

The team showed that additive manufacturing, also known as 3D printing, allows the metal to cool and solidify much faster. They focused on laser bed powder fusion (LBPF), a process in which layers of metal powder are selectively melted by a laser and rapidly solidify before the next layer is added. This rapid freezing preserves the fine precipitate structure predicted by the machine learning model.

"Sometimes we have to think about how to get a material to be compatible with 3D printing," says Hart. "Here, 3D printing opens a new door because of the unique characteristics of the process -- particularly, the fast cooling rate. Very rapid freezing of the alloy after it's melted by the laser creates this special set of properties."

Testing Confirms Record Strength

To validate their design, the researchers ordered a batch of printable metal powder based on the new alloy formula. The powder -- made from aluminum combined with five additional elements -- was sent to collaborators in Germany, who printed small test samples using their LPBF equipment.

Those samples were then shipped back to MIT for mechanical testing and microscopic analysis. The results confirmed the machine learning predictions. The printed alloy was five times stronger than a cast version of the same material and 50 percent stronger than aluminum alloys designed using conventional simulations alone.

Microscopic imaging revealed a dense population of small precipitates, and the alloy remained stable at temperatures up to 400 degrees Celsius -- an unusually high threshold for aluminum-based materials.

The research team is now applying the same machine learning techniques to refine other properties of the alloy.

"Our methodology opens new doors for anyone who wants to do 3D printing alloy design," Taheri-Mousavi says. "My dream is that one day, passengers looking out their airplane window will see fan blades of engines made from our aluminum alloys."

Story Source:

Materials provided by Massachusetts Institute of Technology. Original written by Jennifer Chu. Note: Content may be edited for style and length.

Journal Reference:

- S. Mohadeseh Taheri‐Mousavi, Michael Xu, Florian Hengsbach, Clay Houser, Zhaoxuan Ge, Benjamin Glaser, Shaolou Wei, Mirko Schaper, James M. LeBeau, Greg B. Olson, A. John Hart. Additively Manufacturable High‐Strength Aluminum Alloys with Coarsening‐Resistant Microstructures Achieved via Rapid Solidification. Advanced Materials, 2025; DOI: 10.1002/adma.202509507

Cite This Page: